Address

Ruko Golden Madrid Blok D No 26 Room 1288 Jl. Letnan Sutopo BSD City RT.005/RW.002 Kelurahan Rawa Mekar Jaya, Kecamatan Serpong, Tangerang Selatan, Banten 15310

Combustible Dust Material

Combustible dusts are those capable of forming a more stable oxide. Typically, particles below 500 microns (Figure 1). Most organic powders and powdered metals are potential combustible dusts. A few examples combustible include: Starch, sugar, flour, tea, coffee, milk powder, flavour and perfume encapsulate, sulphur, salicylic acid, avobenzone, coal, scrapped metal and many more.

There are 3 hazards from Dust. Fire, If the dust is deposited in layers, then these layers can be ignited and spread a fire either slowly. Flash Fire / Explosion, If the dust exists as a cloud, e.g. during transfer operations then if ignited a flash fire can occur. If this is confined and over pressure is generated then this is an explosion. Operator Health, many of the materials handled in industry represent a health hazard if inhaled by or deposited on the skin an operator.

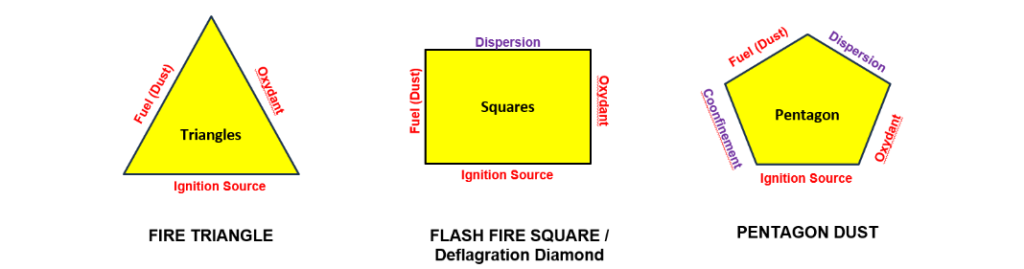

Triangle of Fire (Fuel, Oxidant, Ignition Sources), Flash Fire square (additional 1 element: dispersion in the air) and Pentagon Combustible Dust (Additional 1 element: Confined Space) are main concept of Fire and Explosion caused by Combustible Dust (Figure 2). By cutting one of the chain simplifying reduce the possibility fire and explosion happened. Avoiding electrical and mechanical spark, electrostatic, hot surface, flame and exothermic reaction from Dust air mixture / dust layer will cut ignition sources chain. Limiting oxygen by introducing gas inert in the hazardous area will cut Oxidizing chain. Managing dust dispersion on the air to avoid Minimum Explosive Concentration.