Address

Ruko Golden Madrid Blok D No 26 Room 1288 Jl. Letnan Sutopo BSD City RT.005/RW.002 Kelurahan Rawa Mekar Jaya, Kecamatan Serpong, Tangerang Selatan, Banten 15310

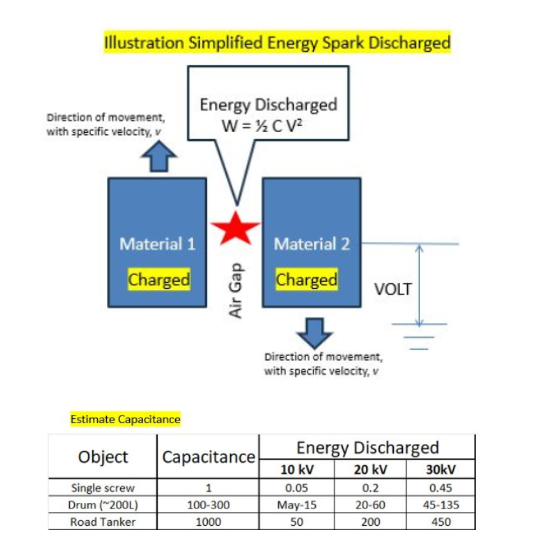

Electrostatic as Ignition Source

In order for an ignition source to ignite, a Dust layer or cloud needs to be effective.

This means ignition sources contain sufficient energy and need to be of sufficient duration to heat the material to a self-sustaining reaction temperature

The key risk assessment parameters for ignition sources are:

1. Minimum Ignition Energy (MIE)

2. Minimum Ignition Temperature: Layer Ignition Temperature for layers and Minimum Ignition Temperature for clouds

In any powder handling operation electrostatic charge can build up on the bulk powder, powder suspension, process equipment and fitting, personnel and object nearby. Contact or friction between two dissimilar substances can produce a charge separation if either of the two substances is an insulator [greater than 10^8 ohm.meter]. Discharged energy between charged powder and other surfaces can be a potential ignition source to ignite dust cloud and can lead to fire and explosion. Neglecting other losses balance of energy will result Spark energy is

W = 1/2 CV2 ……… (1)

where,

(W) Discharged energy;

(C) Capacitance of nonrounded material and

(V) Voltage generated during powder separation.

Comparing Spark Energy and Minimum Ignition Energy of the material. If Spark energy is higher than MIE then fire/explosion could occur.

Voltage generated because of electrostatic is able to measure by Electrostaticmeter. Applying equation 1 above will result the discharge energy during normal operation.